Twin Screw Plastr Extruder (PET Yerekana Urupapuro)

Ikigereranyo cya tekiniki

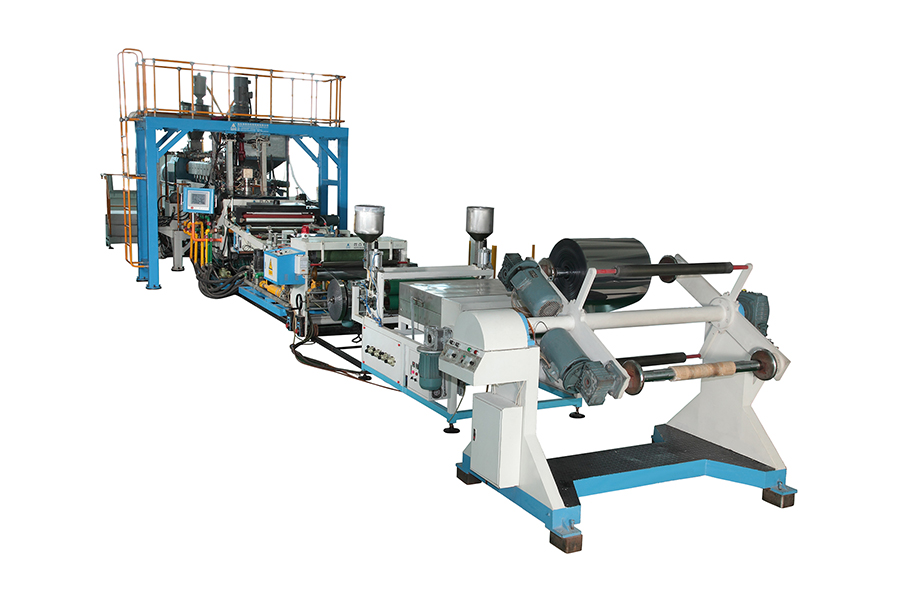

WJP (PET) 75B-1000 Twin Screw Plastr Extruder (Urupapuro rwerekana urupapuro)

| Ibikoresho bifatika | Kugaragaza neza | Ubunini bw'urupapuro | Ubugari bw'urupapuro | Ubushobozi bwo gukuramo | Ubushobozi bwashyizweho |

| mm | mm | mm | kg / h | kW | |

| APET , PLA | Φ75 | 0.18-1.5 | 50850 | 300-400 | 280 |

Ibiranga

1.Ibikoresho bya screw bifata ubwoko bwa conjugate bwikubitiro bubiri hamwe nigishushanyo mbonera cya mudasobwa hamwe no gutunganya neza. Byongeye kandi, screw yateguwe hamwe nubwubatsi butandukanye bwubatswe bwubaka, bufite isuku yo kwisukura no guhinduranya.

2. Ukurikije imyaka yuburambe bwibishushanyo mbonera, AUTO irashobora gukora iboneza ryiza ryibikoresho bya screw hamwe nubufasha bwa tekinoroji ya software. Kubwibyo, irashobora gutahura ihererekanyabubasha ryibikoresho bya pulasitiki, gutunganya kuvanga, kogosha no gutatanya, homogenisation, guhindagurika no devolatilisation, gukomeza igitutu no gusohora nindi mirimo ukurikije ibikoresho byabakiriya nubuhanga bwo gutunganya.

3. Imashini ya mashini yateguwe hamwe na vacuum ebyiri zuzuza ibyuma bisohora imyuka y'amazi hamwe nizindi myuka ihindagurika.

4.

5. Imashini yose ikoresha sisitemu yo kugenzura PLC, ishobora kumenya kugenzura byikora kugena ibipimo, igenekerezo ryumunsi, ibitekerezo, gutera ubwoba nibindi bikorwa.

Ibyiza

Kimwe mu bintu by'ingenzi byaranze impanga zacu za plastike ni ibintu byabo. Hafashwe ingamba zikomeye kugirango habeho gukora neza no kuramba ukoresheje imashini ihuza impanga. Igishushanyo cyihariye cyahujwe na tekinoroji yo gukoresha mudasobwa hamwe no gutunganya neza, bivamo imikorere isumba iyindi. Ibikoresho bya screw binagaragaza ubwubatsi bwuburyo bwo kwisukura no guhinduranya. Ibi bituma inzira yumusaruro igenda neza kandi idahagarikwa, kugabanya igihe cyateganijwe no kongera umusaruro.

Imyaka yuburambe muburyo bwa screw ibishushanyo bidufasha kurushaho kunoza imikorere ya extruder. Hamwe nubufasha bugezweho bwa tekinoroji ya software, turashobora gushiraho neza ibice bigize screw. Ibi bivuze ko abadusohora bashobora kwimura no gutunganya ibintu neza, byemeza umusaruro uhoraho. Tekinoroji ya software yacu igira uruhare runini mugushikira uburyo bwiza bwo gukora, kwemeza ko abakiriya bacu bashoboye gutanga urwego rwo hejuru rwurupapuro rwa PET.

Iyindi nyungu yingenzi ya twin screw twibikoresho bya plastike ni byinshi. Waba urimo gukora urupapuro rwa PET yo gupakira, thermoforming cyangwa ikindi kintu icyo aricyo cyose, abadusohora barashobora kuguha ibyo ukeneye bidasanzwe. Irashoboye gutunganya ibikoresho bitandukanye, itanga ihinduka ryinshi mubikorwa byawe. Byongeye kandi, extruders yacu yagenewe guhinduka byoroshye kandi byihuse, bikwemerera guhinduka byoroshye muburyo butandukanye bwibicuruzwa. Ubu buryo butandukanye bugutwara igihe n'amafaranga, bigatuma abadusohora badashaka igisubizo cyigiciro cyibikoresho bya PET ukeneye.